The oil and gas industry plays a central role in the global energy system, but it also operates in environments with extremely high safety risks. Flammable substances such as crude oil, natural gas, naphtha, and hydrogen are commonly present throughout the production, processing, storage, and transportation processes, resulting in a constant risk of forming explosive atmospheres when these substances mix with air in the presence of an ignition source. Hence, much of the industry’s operational environment is classified as hazardous areas, where equipment must meet stringent explosion protection requirements.

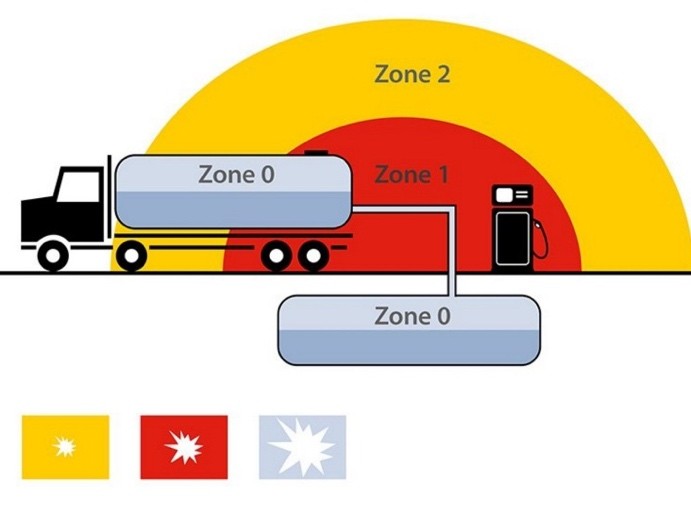

To more effectively manage explosion risks, hazardous areas are categorized based on the frequency and duration of explosive gas atmospheres. The most common classifications are:

Zone 1: An area where an explosive gas atmosphere is likely to occur occasionally during normal operation.

Zone 2: An area where an explosive gas atmosphere is unlikely to occur during normal operation, and if it does occur, it will exist only for a short period.

Each zone requires equipment with different levels of explosion protection, known as Equipment Protection Levels (EPL). For example, devices used in Zone 1 must meet Ga or Gb protection levels, while Zone 2 allows for Gc-rated equipment.

The oil and gas industry demands strict explosion protection for all electrical and mechanical equipment used in hazardous areas. Equipment deployed in these environments must comply with internationally recognized certification systems, namely IECEx and ATEX.

IECEx, developed by the International Electrotechnical Commission (IEC), is a global system for certifying equipment intended for use in explosive atmospheres.

ATEX is the European Union’s mandatory directive for such environments, composed of two main directives:

o ATEX 2014/34/EU (Equipment Directive): Regulates the design and application of equipment and protective systems in potentially explosive atmospheres.

o ATEX 1999/92/EC (Workplace Directive): Specifies minimum safety and health requirements for workplaces in explosive environments.

Both IECEx and ATEX use standardized symbols and alphanumeric codes to classify explosion risk levels, equipment categories, and intended use environments. These codes help industries ensure proper selection, installation, and safe operation of equipment in defined zones.

In the oil and gas sector, hazardous area classification and compliance with IECEx/ATEX standards are not merely regulatory obligations—they are critical for ensuring intrinsic safety, operational stability, and the protection of human life. Any electrical device operating in a Zone 1 or Zone 2 environment must be certified for explosion protection. Equipment built to meet IECEx or ATEX standards forms the foundation for safe, reliable operations in some of the world’s most dangerous industrial settings.