Gerchamp G-TH is the first 12v battery monitoring system designed for data centers and critical power facilities. It uses intelligent algorithm analysis, can monitor the battery voltage, internal resistance and negative temperature in real time, provides SOC accuracy of up to ± 5%, and has the early warning function of thermal runaway to ensure the safe operation of the backup power system, and can be purchased in bulk.

Monitoring voltage:

2V/6V/12V

SOC Accuracy:

± 5%

Sleep power consumption:

≤ 3mA

For technical teams managing large-scale server rooms, Gerchamp G-TH 12v battery monitoring system provides high-density monitoring capabilities. It can ensure the absolute reliability of UPS backup power supply in the moment of power failure, and prevent data loss or service interruption caused by battery failure.

For engineers deploying backup power in harsh environments, such as offshore drilling platforms or refineries. The G-TH’s wide temperature operating range (-20°C to +60°C) and robust industrial-grade stability can meet the stringent requirements of the petrochemical industry for equipment reliability and safety.

For power engineers responsible for subway, high-speed rail signal system and emergency lighting. The system can centrally monitor the batteries distributed along the line, reduce the cost of manual inspection on the station, and ensure the power supply safety of key rail transit facilities.

For infrastructure managers at bank headquarters and securities trading centres. Due to the high continuity requirements of financial services, the high-precision SOC/SOH analysis provided by the G-TH can help managers accurately plan the battery replacement cycle and avoid huge economic losses caused by unexpected downtime.

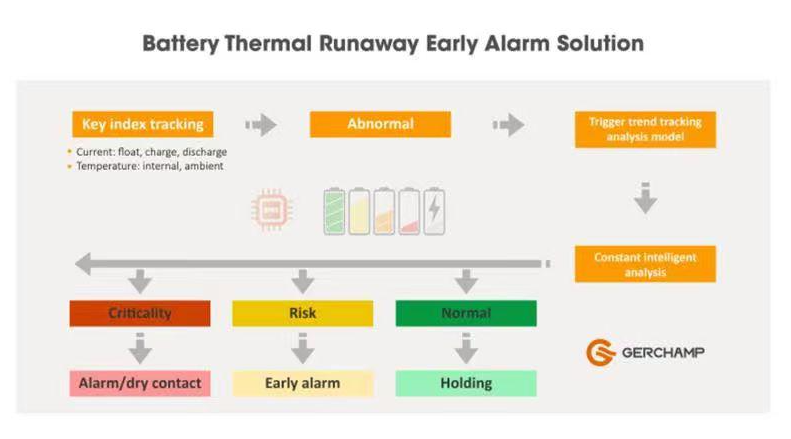

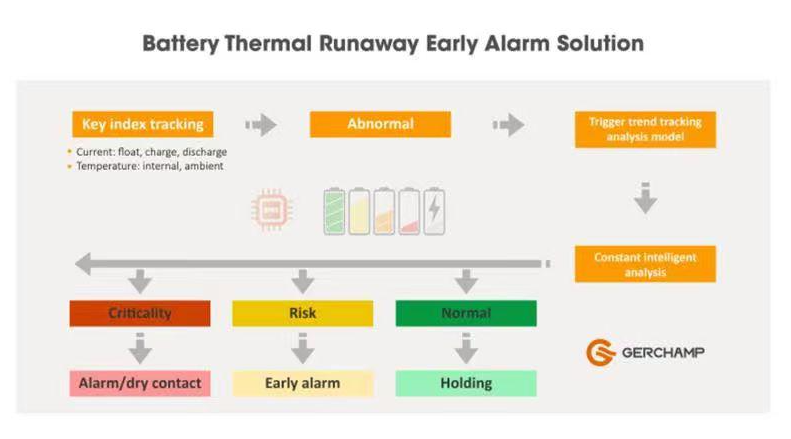

The Gerchamp G-TH system not only records data, but also uses built-in algorithms for intelligent analysis by monitoring the trend of floating charge flow and temperature change. It can issue an early warning before the irreversible thermal runaway of the battery occurs, so that the operation and maintenance personnel have enough time to intervene, avoid the occurrence of catastrophic accidents such as fire, and ensure the safety of infrastructure.

In view of the problem of inaccurate estimation of traditional monitoring system, the 12v battery monitoring system combines Kalman filtering and fuzzy neural network algorithm. This technology realizes online parameter identification, improves the calculation accuracy of SOC and SOH to 5%, which is significantly better than the industry average level, and effectively prolongs the service life of the battery pack.

In order to reduce the impact of the monitoring device itself on the battery pack, the G-TH module adopts an advanced low-power circuit design. The module maintains a consistent low power consumption of 3mA during 24h real-time monitoring (well below the 10mA + level common in the industry). This means that even in the case of long-term floating charge or power failure, the monitoring system will not consume excessive battery energy, ensuring the stability of continuous operation without the need for a sleep mode.

The system can carry out fine management of each 1 battery, and collect battery voltage, battery internal resistance and negative column temperature in real time. The G-TH provides accurate data support for the entire battery string, ensuring that maintenance personnel can identify potential risks before a single battery failure impacts the system.

The G-TH system features a modular design that allows for rapid deployment in existing or new battery rooms. Its standardized connectors and intuitive wiring logic significantly reduce the complexity of on-site implementation, enabling technical teams to complete the system setup with minimal downtime and lower labor costs.

To ensure critical issues are never missed, the G-TH provides a sophisticated multi-level alarm system. Users can define specific thresholds for different parameters based on their facility’s safety protocols. This ensures that minor deviations trigger early warnings while critical failures initiate immediate high-priority alerts across various communication channels.

| Parameter Item | Specification Details |

| Product Name | G-TH 12v Battery Monitoring System |

| Cell Voltage | 1.2V, 2V, 6V, 12V |

| Voltage Accuracy | ±0.1% |

| Internal Resistance Range | 50 ~ 65535 μΩ |

| Resistance Repeatability | ±2% |

| Temperature Range | -5°C ~ +99.9°C |

| Temperature Accuracy | ±1°C |

| SOC/SOH Accuracy | ±5% |

| Operating Temperature | -20°C ~ +60°C (0~2000mASL) |

| Communication Protocol | Modbus-RTU / UART |

| Certification | UL, CE, REACH |

Gerchamp G-TH has significant advantages at the algorithm level, unlike the monitoring devices on the market that rely only on simple threshold alarms, G-TH use intelligent algorithm analysis. This allows the system to predict the risk of thermal runaway in advance through small trends in float current and temperature, rather than just post-alarm. In terms of hardware power efficiency, the Gerchamp G-TH features an ultra-low-power design. It is G-TH controlled within 3mA. This design significantly reduces the power consumption of the monitoring system on the battery itself, and in particular ensures the long-term health of the battery pack in applications with long-cycle backup power.

Aiming at the hidden danger of lead-acid batteries that are prone to thermal runaway and cause fires, we have solved the problem that the traditional system cannot identify the battery overheating trend in advance, and transformed passive fire protection into active prevention.

Gerchamp G-TH is the first 12v battery monitoring system designed for data centers and critical power facilities. It uses intelligent algorithm analysis, can monitor the battery voltage, internal resistance and negative temperature in real time, provides SOC accuracy of up to ± 5%, and has the early warning function of thermal runaway to ensure the safe operation of the backup power system, and can be purchased in bulk.

2V/6V/12V

Monitoring voltage:

± 5%

SOC Accuracy:

≤ 3mA

Sleep power consumption:

The Gerchamp G-TH system not only records data, but also uses built-in algorithms for intelligent analysis by monitoring the trend of floating charge flow and temperature change. It can issue an early warning before the irreversible thermal runaway of the battery occurs, so that the operation and maintenance personnel have enough time to intervene, avoid the occurrence of catastrophic accidents such as fire, and ensure the safety of infrastructure.

In view of the problem of inaccurate estimation of traditional monitoring system, the 12v battery monitoring system combines Kalman filtering and fuzzy neural network algorithm. This technology realizes online parameter identification, improves the calculation accuracy of SOC and SOH to 5%, which is significantly better than the industry average level, and effectively prolongs the service life of the battery pack.

In order to reduce the impact of the monitoring device itself on the battery pack, the G-TH module adopts an advanced low-power circuit design. The module maintains a consistent low power consumption of 3mA during 24h real-time monitoring (well below the 10mA + level common in the industry). This means that even in the case of long-term floating charge or power failure, the monitoring system will not consume excessive battery energy, ensuring the stability of continuous operation without the need for a sleep mode.

The system can carry out fine management of each 1 battery, and collect battery voltage, battery internal resistance and negative column temperature in real time. The G-TH provides accurate data support for the entire battery string, ensuring that maintenance personnel can identify potential risks before a single battery failure impacts the system.

The G-TH system features a modular design that allows for rapid deployment in existing or new battery rooms. Its standardized connectors and intuitive wiring logic significantly reduce the complexity of on-site implementation, enabling technical teams to complete the system setup with minimal downtime and lower labor costs.

To ensure critical issues are never missed, the G-TH provides a sophisticated multi-level alarm system. Users can define specific thresholds for different parameters based on their facility’s safety protocols. This ensures that minor deviations trigger early warnings while critical failures initiate immediate high-priority alerts across various communication channels.

| Parameter Item | Specification Details |

| Product Name | G-TH 12v Battery Monitoring System |

| Cell Voltage | 1.2V, 2V, 6V, 12V |

| Voltage Accuracy | ±0.1% |

| Internal Resistance Range | 50 ~ 65535 μΩ |

| Resistance Repeatability | ±2% |

| Temperature Range | -5°C ~ +99.9°C |

| Temperature Accuracy | ±1°C |

| SOC/SOH Accuracy | ±5% |

| Operating Temperature | -20°C ~ +60°C (0~2000mASL) |

| Communication Protocol | Modbus-RTU / UART |

| Certification | UL, CE, REACH |

For technical teams managing large-scale server rooms, Gerchamp G-TH 12v battery monitoring system provides high-density monitoring capabilities. It can ensure the absolute reliability of UPS backup power supply in the moment of power failure, and prevent data loss or service interruption caused by battery failure.

For engineers deploying backup power in harsh environments, such as offshore drilling platforms or refineries. The G-TH’s wide temperature operating range (-20°C to +60°C) and robust industrial-grade stability can meet the stringent requirements of the petrochemical industry for equipment reliability and safety.

For power engineers responsible for subway, high-speed rail signal system and emergency lighting. The system can centrally monitor the batteries distributed along the line, reduce the cost of manual inspection on the station, and ensure the power supply safety of key rail transit facilities.

For infrastructure managers at bank headquarters and securities trading centres. Due to the high continuity requirements of financial services, the high-precision SOC/SOH analysis provided by the G-TH can help managers accurately plan the battery replacement cycle and avoid huge economic losses caused by unexpected downtime.