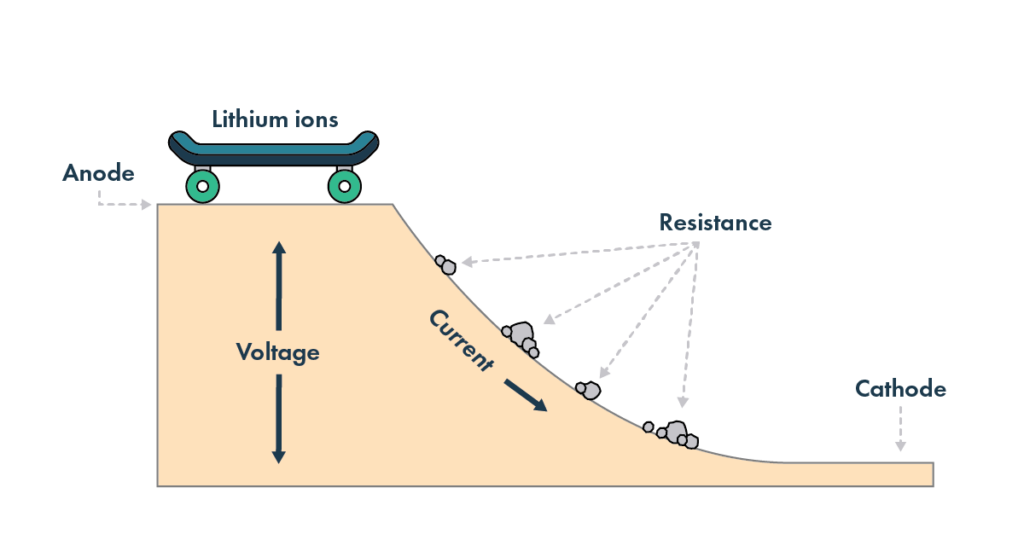

With the widespread adoption of lithium-ion batteries in energy storage systems, concerns regarding their performance, safety, and lifespan have significantly increased. Behind these critical performance indicators lies an often overlooked yet essential parameter—Internal Resistance (IR).

The role of internal resistance in lithium-ion batteries

• Temperature: When Cold Becomes a Challenge

Temperature is the primary factor influencing internal resistance. Under low-temperature conditions, ion diffusion rates slow, and electrolyte conductivity decreases, causing a rapid rise in internal resistance. Particularly below -20°C, both bulk impedance and SEI (Solid Electrolyte Interphase) film impedance significantly increase, leading to a noticeable deterioration in battery performance.

• SOC Levels: More Charge Isn’t Always Better

The DC internal resistance of lithium-ion batteries increases with the Depth of Discharge (DOD). Within the 10%–80% State of Charge (SOC) range, internal resistance remains relatively stable. However, at extremely high DOD or fully charged states, internal resistance increases sharply, adversely affecting power output. Thus, extreme charge-discharge behaviors in practical energy storage system operations significantly impact battery power output and thermal management.

• Storage Time: Aging in Silence

Internal resistance continuously increases even when batteries are unused over extended periods, especially under high SOC and high-temperature conditions. Regular inspection and maintenance of battery performance are essential for backup energy storage systems.

• Cycling: Deeper, Hotter = Faster Degradation

With increasing charge-discharge cycles, phenomena such as active material depletion, structural degradation, and accumulation of side reaction products lead to thicker SEI films and deteriorating electrode interfaces, ultimately manifesting as a gradual rise in internal resistance. Optimizing charging and discharging strategies and controlling temperature conditions are crucial for delaying internal resistance increase and extending battery cycle life.

Chages in lithium-ion battery internal resistance profoundly and directly affect the actual performance, safety, and economics of energy storage systems.

• Reduced Power Output: Higher internal resistance results in greater voltage drops, leading to decreased power density.

• Increased Heat Generation: According to P = I²R, higher currents combined with increased internal resistance lead to greater thermal losses, escalating thermal management pressures, and potential thermal runaway risks.

• SOC Estimation Errors: Dynamic internal resistance variations affect the accuracy of Battery Management System (BMS) in voltage-to-capacity mapping.

• Lower Charge-Discharge Efficiency: Increased energy conversion losses result in reduced overall system efficiency.

As a critical indicator for evaluating lithium-ion battery health and performance, internal resistance directly impacts the efficiency, safety, and service life of energy storage systems. Scientific monitoring and effective management of internal resistance enhance overall system performance and reliability. In today’s expanding applications of energy storage, prioritizing internal resistance management has become an integral component of achieving sustainable and efficient operation.